CNC Inoshandura mhando simbi isina simbi / aluminium inochinjika coupling yemota

Curved Jaw Couplings

Iyo Curved Jaw couplings inogona kushandiswa mune akawanda maapplication uye inoshanda seyese-chinangwa coupling.Iyo yakakosha dhizaini yeCurved Jaw inobvumira kune yakakwira torque huwandu mune compact dhizaini.Zino rakakomberedzwa rine nzvimbo yakakura yekusangana iyo inopa iyo yakakwirira torque kugona, uye inoderedza kumucheto kudzvanywa.Ichagadzirisa axial, radial uye angular shaft misalignments.

Iyo hubs inogadzirwa kubva kwakasiyana-siyana zvinhu zvinosanganisira: aluminium, grey, simbi, simbi, sintered simbi, uye simbi isina tsvina.Iyo spider elements inowanikwa mune dzakasiyana siyana durometer sarudzo muUrethane & Hytrel.Madandemutande anogona kuita pasi peyakajairika basa kutenderera mamiriro kune inorema basa macycles anosanganisira kuvhunduka kurodha uye anogona kuderedza torsional vibrations muhurongwa.

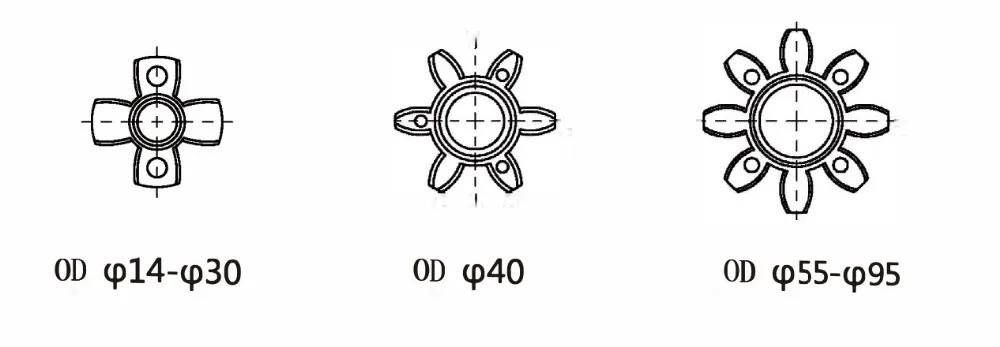

| Model | Bore size (mm) | RatedTorque (Nm) | MaxTorque(Nm) | Max speed | Kunze Diameter (mm) | Urefu (mm) | Bore Tolerance (mm) |

| HS -TCN-14C | 3~7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6~0 |

| HS-TCN-20C-R | 4~11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0.8~0 |

| HS-TCN-30C-R | 6~16 | 4 | 8 | 21000 | 30 | 35 | +1.0~0 |

| HS-TCN-40C-R | 8~28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1.2~0 |

| HS-TCN-55C-R | 9.5~32 | 17 | 34 | 11000 | 55 | 78 | +1.4~0 |

| HS-TCN-65C-R | 12.7~38.1 | 46 | 92 | 9000 | 65 | 90 | +1.5~0 |

Spider Characteristics

Iyo yakakomberedzwa shaya yekubatanidza inosanganisira maviri simbi hubs uye elastomeric "spider" element.Madandemutande anowanikwa mukati

akasiyana kuomarara durometers, imwe neimwe nyore kuzivikanwa nemuvara wayo.

| Kuoma | Color | Material | Temperature Range | Applications |

| 80 Shore A | Bhuruu | Polyurethane | -50 ~+80 .C | Excellent damping |

| 92 Shore A | Yero | Polyurethane | -40~+90 .C | Kunyorovesa zvine mwero, zvakajairika zvikumbiro |

| 98 Shore A | Tsvuku | Polyurethane | -30 ~+90 .C | High torque application |

| 64 Shore D | Girinhi | Polyurethane | -50 ~+120 .C | Yakakwirira torque, yakakwirira tembiricha |

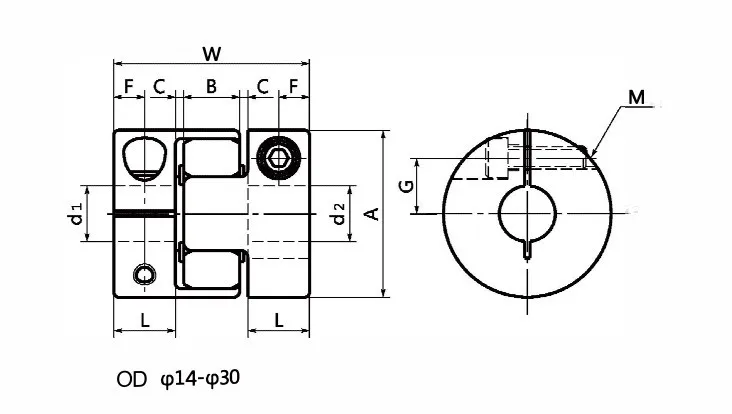

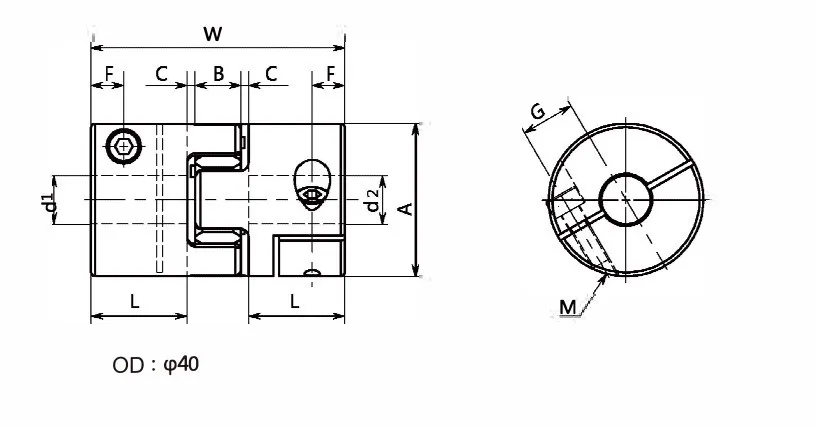

Coupling chiyero ruzivo

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |